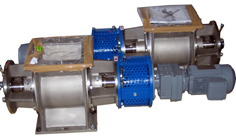

Rotary Valve

For the efficient dosing of bulk goods of all kinds from silos and bunkers

Areas of application

The rotary valves are designed for the measured discharge of powdered bulk goods from silos or bins.

According to application, the cast housings are hard-chrome plated inside or as sturdy welded construction. Steel or stainless steel bucket wheels with 8 - 10 partially slanted cells guarantee quiet running and high operational safety. For the drive, flanged gear motors connected directly via a coupling or through a chain reduction unit are available. Varying rotational drive speeds and chain gear ratios, hand adjsutable control gears or frequency controlled motors permit a fine gradation of the discharge output.

Rotary valves type SZR are suitable for discharge qunatities up to 36 m3/hr.

Because of their Vulkano gasket moldings this type is especially suited for the attachment of a blow-out shoe. Even very small quantities can be dosed via special bucket wheels.

Discharge outputs up to more than 300 m3/hr. are facilitated with the series types N and UL.

Large-dimensioned roller bearings with radial seals and slanted rotor blades guarantee quiet running and little blockage of the rotor. The type UL with external bearings is suitable for the dosing of hot and abrasive bulk goods, such as, for example, fly-ash and cement. The external bearings guarantee longer service life.

Operation

Rotors with 8 - 10 cells dose the bulk goods and the rotational speed of the drive motor determines the dosing quantity. A change in the dosing quantity can be effected via a change of the chain wheel, a hand control unit or with frequency controlled motors. Bulk goods can be blown optimally in a low-pressure environment via blow-out shoe and leaking-air removal.

Material/Design

Rotary valves of the type SZR with cast housing and rotor blades for small to medium discharge quantities are made of steel or stainless steel. Type N and UL rotary valves are hard chrome-plated inside with ground cast iron housings and rotor blades of steel or stainless steel and with slanted rotor blades.

Sizes 200/620 and 300/650 are of heavy, welded construction. Lacquering is hammertone, siver grey;

other finishes on request.

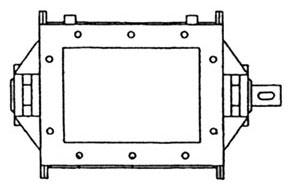

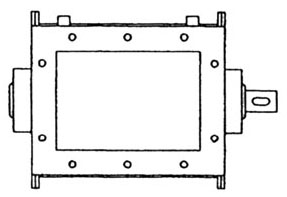

| Rotary Valve TYP N Bearing integrated into bearing cover |

Rotary Valve TYP UL with external bearings |

|---|---|

|

|

Technical data

Rotary valves aith the motor placed above the chain wheels permit a short building style. Rotary speed control and large-sized motors with temperature control via posistors assure operational safety.

Advantages

- Permanently lubricated ball bearings

- Quiet running due to slanted cells of the bucket wheel

- Wear protection through hard-chrome plating